Custom Microwave MUX Switch for MRI Automated Test Equipment

New system for Philips Healthcare delivered quickly with uprated spec

|

"We are very happy with the result. This was a complex challenge, but now we have a better system that is 100% compatible with our established working practices, and Pickering delivered it on time and on budget."

|

When Dutch giant Philips Healthcare was looking for a replacement for a microwave multiplexer switch used within its in-house,

automated test equipment (ATE) for medical imaging scanners, it faced the challenge of selecting a partner with the engineering

expertise to develop such a part and the flexibility to deliver fast.

Philips Healthcare has a worldwide reputation for product quality and reliability. Central to the company's functional ATE for its medical imaging product range is a GPIB-controlled, 32:1 microwave multiplexer switch, which Philips had been using for several years. This product was being made obsolete by the manufacturer, so Philips had to find another solution. Also, the part needed to be easily integrated within the ATE, and time was pressing. Philips' preference was to find a supplier that could handle both hardware and software design and produce a unit that used the same BNC front panel connectors as the existing switch.

The ATE system used by Philips has strict requirements.

The magnetic resonance system comprises around 32 different coils, and the data acquisition has only one output, hence the need for an RF switch. The RF signal is less than 1MHz, but the challenge is to keep the integrity of the waveform during switching. In other words, the wave shape containing higher frequency harmonics (pulse) must not be impacted by the switch.

Pickering Interfaces was already known to Philips Healthcare but didn't have such a switch module in its wide product range. However, Pickering agreed to design one from scratch. Philips had two options:

- Copy the existing tester and integrate the Pickering switch

- Design and build a brand-new system

When designing the new switch module, Pickering used high spec 18GHz relays to ensure signal integrity was not degraded. The new design includes LED-energized path indicators that were not available on the original switch, and 36 mux channels were provided—four more than the original module—to allow for future expansion. Finally, Pickering's engineering team was able to produce the unit in a 2U high enclosure, 1U less than the unit it replaces.

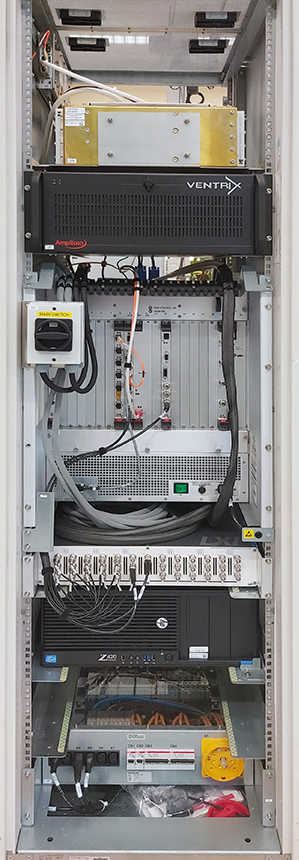

Philips Healthcare ATE containing Pickering's LXI Microwave MUX (model 60-891-001-002)

Software was developed and evaluated at Philips using Pickering's LXI simulation tool (model 60-901) configured with the new switch. The LXI simulator accelerated the development and integration process by providing real-time hardware-like feedback, which helped the engineers at Philips develop and verify their code effectively.

To ensure that no additional changes are needed on the users LabVIEW™ application, Pickering provided specific versions of LabVIEW drivers, which integrated seamlessly in their application. Along with the driver, Pickering also provided different example programs and remote training sessions to ensure a smooth transition.

To date, four of the new LXI microwave multiplexer modules have been delivered to Philips Healthcare. Commented Harrie van den Oever, Electrical Engineer at Philips: "We are very happy with the result. This was a complex challenge, but now we have a better system that is 100% compatible with our established working practices, and Pickering delivered it on time and on budget."

Turnkey LXI Microwave Switch & Signal Routing Subsystem Service

Since the development with Philips Healthcare, Pickering has formally launched a turnkey LXI microwave switch and signal routing subsystem service, delivering custom-engineered solutions, like this one, created to customers' specifications. Integrated microwave test packages include switches, Switch Path Manager signal routing software, a dedicated soft front panel, all the wiring and more in a suitable enclosure, and supplied fully tested, with documentation and a three-year warranty.

The service provides compact, rack-mount multiplexer and matrix designs based on an industry-standard LXI/Ethernet interface, designed and manufactured by Pickering's switching experts team. Solutions are available with bandwidths from DC to 67 GHz @ 50 Ω, with terminated or unterminated options (bandwidths up to 2.5 GHz @ 75 Ω).

These cost-effective microwave test packages are available on a fast turnaround and are fully documented to ensure performance repeatability in subsequent engagements. Pickering's familiar standard switch API programming environment accelerates software integration.

Comments Keith Moore, CEO, Pickering Interfaces: "This is an exciting new business direction for Pickering. More and more, our customers are asking for out-of-the-box solutions that are complete and ready-to-run with minimal fuss and set-up time. We have the expertise and ability to turn your high-level requirements for a microwave switching subsystem into a fully integrated solution. You provide us with your unique configuration and specification. Our engineers will work closely with you to provide a well-defined and supportable end product that delivers everything a microwave test engineer needs to get a complex microwave test system up and working the first time."

Also, Pickering can turn a custom design into an 'off-the-shelf' product, offering product support for more than 15 years.

Pickering also offers other microwave switching configurations and is developing a range of additional turnkey switching

and signal routing subsystems, which will similarly be tailored to suit a customer's needs and offered as a boxed system

solution for fast and simple installation.